Profs. Junheng Zhang and Daohong Zhang made progress and their work on recycling of tough epoxy supramolecular thermosets constructed with hyperbranched topological structure was published at Nature Commun. on Jun. 7th, 2024. It is titled 'Closed-loop recycling of tough epoxy supramolecular thermosets constructed with hyperbranched topological structure'.

Prof. Junheng Zhang is the first author and one of the three corresponding authors, besides profs. Hongjun Zhang and Daohong Zhang. SCMU is the first corresponding unit.

Epoxy resin has excellent corrosion resistance, mechanical properties, and processability, and is widely used in aerospace, wind power, and other fields. However, epoxy resin still faces challenges such as the contradiction between strength and toughness, and the difficulty in degrading and recycling cured products. To this end, the hyperbranched polymer team at South-central Minzu University introduced hyperbranched topological structures into epoxy resins, made this progress and published the results in this top journal.

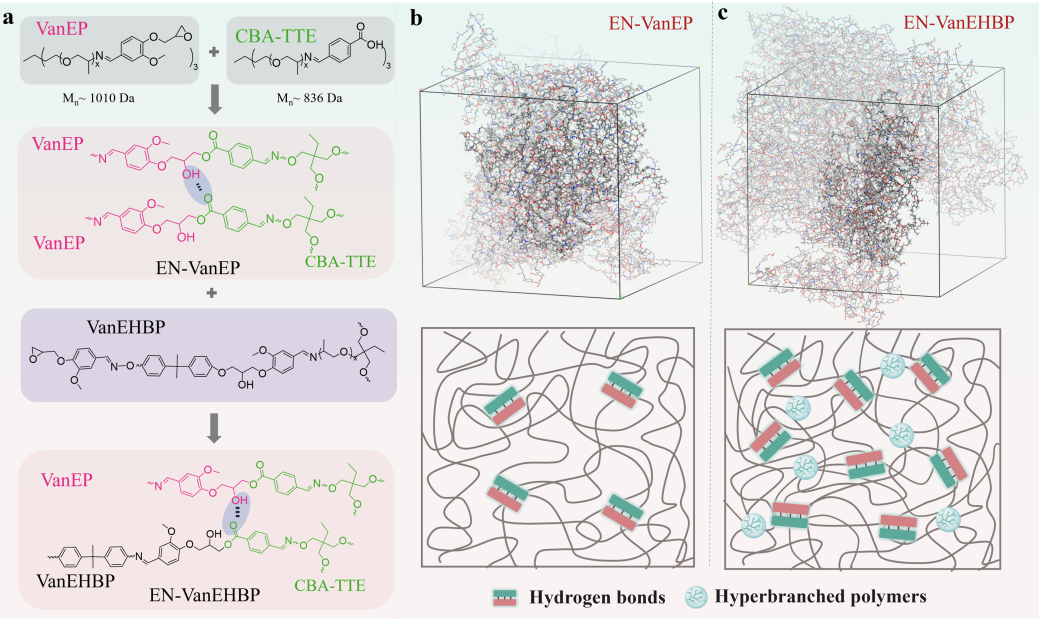

The team has successively involved in the construction and structural control of hyperbranched epoxy resins (Chem. Eng. J: 2018, 334, 1371; Polymer, 2019, 164, 154; Prog. Mater. Sci. 2022, 130, 100977), efficient reinforcement and toughening of epoxy resin (Adv. Mater., 2024, 36, 2308434; ACS Macro Lett, 2021, 10, 1113; Macromolecules, 2022, 55, 595; Chem. Eng. J., 2023, 465, 142998; 2023, 471, 144329). A series of achievements have been made in the efficient degradation and recovery of epoxy resins (Nat. Sustain., 2020, 3, 29; Green Chem., 2022, 24, 6900; Polymers, 2023, 56, 5290; ACS Sustain. Chem. Eng., 2023, 11, 11077), and the preparation methods and recycling strategies of bio based hyperbranched epoxy resins have been systematically summarized (Chem. Soc. Rev., 2024, 53, 624). This work proposes the construction of a closed-loop recyclable epoxy resin based on hyperbranched molecular topology, which contains hydrogen bond crosslinking, dynamic ester exchange, and dynamic imine exchange supramolecular networks (Figure 1). This endows the epoxy resin with high strength, high modulus, and high toughness, and its mechanical properties comprehensivel y surpass those of commercial bisphenol A-type epoxy resin. The high strength and toughness of supramolecular epoxy resin stem from the topological structure of the supramolecular network. Through simulation calculations, the hydrogen bond dissociation and recombination process and motion mechanism of supramolecular epoxy resin were further revealed. The hyperbranched polymer with highly branched structure achieves the reduction and densification of the free volume pore size of epoxy resin, endowing the material with high strength. The high-density hydrogen bonds induced by hyperbranched polymers increase the energy dissipation capacity of the entire network system through reversible fracture and reconstruction under external forces, endowing it with high toughness. In addition, the supramolecular epoxy resin has recyclable processing and self-healing properties, achieving degradation and recovery at room temperature, with a mechanical property repair rate close to 100%, successfully achieving closed-loop chemical recovery of epoxy resin. This innovative work provides a new approach for constructing high-performance epoxy resins with high strength, toughness, degradability, and recyclability, which is of great significance for promoting the sustainable development of circular economy in polymer materials.

Congratulations to both of them!

The hyperbranched polymer team led by prof. Daohong Zhang has been engaged in the synthesis and application research of hyperbranched polymers for a long time. The team has presided over 15 key projects/general/youth projects of the National Natural Science Foundation of China, more than 30 major provincial and enterprise commissioned projects, and has been authorized with more than 70 international and national invention patents. The achievements have won two first prizes of the China Petroleum and Chemical Industry Federation Science and Technology Invention Award and one first prize of the Hubei Province Science and Technology Invention Award. The industrialization of hyperbranched polymer series products has been achieved, and the largest annual production demonstration line of thousand ton hyperbranched polymers in China has been built. It provides hyperbranched polymer research products for more than 200 universities and research institutes in China, and high-performance energy-saving processing aids and key technologies for more than 400 domestic and foreign engineering plastic processing enterprises, promoting the sustainable and healthy development of domestic polymer materials.

Read more:

https://doi.org/10.1038/s41467-024-49272-3

https://www.nature.com/articles/s41467-024-49272-3

https://www.scuec.edu.cn/hxx/info/1020/4401.htm